Nunc a egestas lacus. Lorem ipsum dolor sit amet, consectetur zunc egestas lacus. Lorem ipsum dolor sit amet. London

© Copyright Qode Interactive

Portland Limestone Cement (aka PLC, Type IL Cement) is uniquely formulated to reduce the environmental footprint of Portland Cement. This cement is manufactured by intergrinding portland cement clinker with up to 15% limestone. Blended cements such as Type IL are used in all aspects of concrete construction in the same manner as portland cements. Blended cements can be used as the sole cementitious material in concrete or they can be used in combination with other supplementary cementitious materials added at the concrete plant. Laboratory tests indicate that the performance of concrete made with Type IL cement as a group is similar to that of Type I/II (MH) cement concrete.

Type IL(MS) Portland Cement is uniquely formulated to provide: 1) the basic performance characteristics of Type IL Portland Cement and 2) the moderate sulfate resistance and lower heat of hydration characteristic of Moderate Sulfate (MS) Resistant Portland Cement Ash Grove South’s Type IL(13)(MS) Portland Cement exceeds all applicable ASTM, Federal, State highway and AASHTO specifications for Portland Cement, and can be shipped by bulk or packaged.

Source: Portland Cement Association

Related Documents (click to view): Spec Data Sheets & Mill Certs

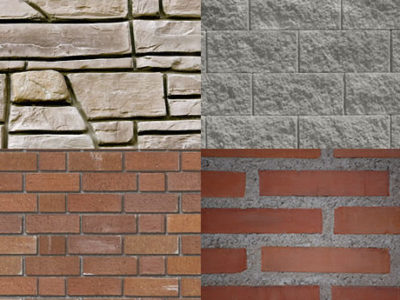

Masonry Cement is a hydraulic cement designed for use in mortar for masonry construction. Masonry cement consists of a mixture of portland cement or blended hydraulic cement and plasticizing materials (such as limestone or hydrated or hydraulic lime), together with other materials introduced to enhance one or more properties such as setting time, workability, water retention and durability. These components are proportioned at the cement plant under controlled conditions to assure uniformity of performance.

Fly ash is a powdery material that is captured by emissions control equipment before it can “fly” up the stack. Mostly comprised of silicas, aluminas and calcium compounds, fly ash has mechanical and chemical properties that make it a valuable ingredient in a wide range of concrete products. Roads, bridges, buildings, concrete blocks and other concrete products commonly contain fly ash.

Concrete made with coal fly ash is stronger and more durable than concrete made with cement alone. By reducing the amount of manufactured cement needed to produce concrete, fly ash accounts for approximately 12 million tons of greenhouse gas emissions reductions each year.

Other major uses for fly ash include constructing structural fills and embankments, waste stabilization and solidification, mine reclamation, and use as raw feed in cement manufacturing.

Source: American Coal Ash Association

Related Documents (click to view): Spec Data Sheets & Mill Certs